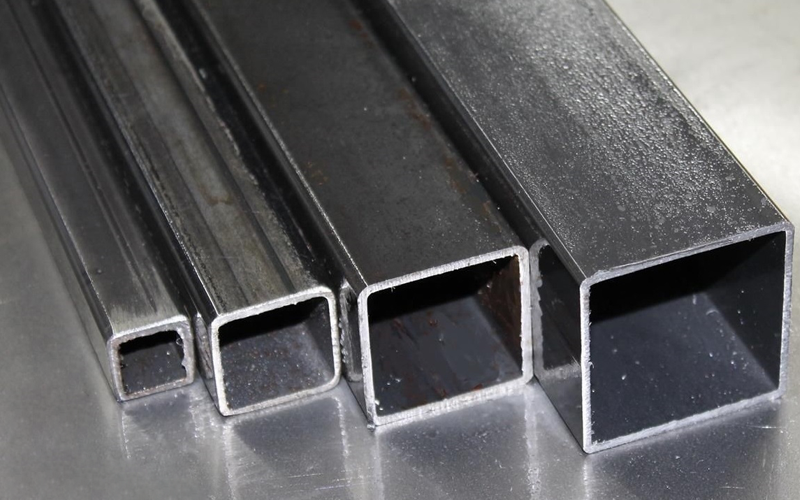

The common size we supply :

| Thickness | Length | ||

|---|---|---|---|

| SHS | 2” x 2” | 2.3mm , 3.0mm | 6m (new / reconditioned) |

| RHS | 2” x 4” , 2” x 3” | 2.3mm | 6m (new / reconditioned) |

Hollow Section Scaffolding Advantages

- Strength: The strength of hollow section scaffolding is one of its main benefits. This scaffolding system is perfect for construction projects where employees need to access elevated work locations since it is built of steel tubes that can handle large weights. The lightweight hollow steel tubes utilised in this scaffolding structure make them simple to transport and erect.

- Versatility: The versatility of hollow section scaffolding is another benefit. This scaffolding system can complete simple repairs to significant construction projects of all sizes. Additionally, it is quite adaptable, enabling workers to change the scaffolding's height, width, and other characteristics to suit their unique requirements.

Hollow Section Scaffolding Components

There are some hollow section scaffolding components, including foundation plates, vertical standards, ledgers, transoms, and diagonal braces. The vertical standards are the vertical tubes that support the scaffolding structure, whilst the base plates are used to secure the scaffolding to the ground. The diagonal braces are used to offer additional stability to the scaffolding construction. The ledgers and transoms are the horizontal tubes that link the vertical standards.Applications of Hollow Section Scaffolding

Construction projects that involve the construction of buildings, bridges, and industrial maintenance frequently use hollow section scaffolding. Along with shipbuilding, oil and gas platforms and other offshore construction projects utilise this scaffolding technology.Get High-Quality Hollow Section Scaffolding

Hollow section scaffolding can be the ideal choice if you're planning a building project and require a sturdy scaffolding system. In construction projects worldwide, hollow section scaffolding is a flexible and long-lasting scaffolding structure. This is where you should find reliable Hollow Section Suppliers! Here at Power Metal & Steel, we take pride in offering our customers high-quality hollow section scaffolding products. Since safety and dependability are crucial in building projects, our Steel Hollow Section Supplier Malaysia provide scaffolding that complies with or exceeds industry standards. We also provide affordable pricing without sacrificing quality. We are also a square hollow section supplier Malaysia that offers scaffolding products at competitive prices that uphold the highest standards of reliability and safety. * Please consult customer service or sales representative for shorter length.What are Hollow Sections?

Hollow sections, also known as tubular sections, are widely used in construction due to their versatility and structural efficiency. These sections are typically made from steel and come in various shapes, including square, rectangular, and circular. Their hollow nature provides an excellent strength-to-weight ratio, making them ideal for applications where strength and lightweight properties are essential. Square hollow sections (SHS) are among the most popular types, valued for their aesthetic appeal and uniform strength. They are easy to fabricate and can be used in a wide range of structural and architectural applications. These sections are integral in the construction of buildings, bridges, and other infrastructure projects, providing a reliable framework that supports heavy loads.Features and Benefits

Strength and Durability

One of the primary benefits of hollow sections is their exceptional strength and durability. Made from high-quality steel, these sections can withstand significant stress and load, making them suitable for demanding construction projects. The hollow structure enhances their ability to distribute weight evenly, reducing the risk of structural failure.

Lightweight

Despite their strength, hollow sections are relatively lightweight. This characteristic simplifies transportation and handling, reducing labor costs and improving construction efficiency. The lightweight nature of these sections also contributes to faster assembly and disassembly of scaffolding systems, enhancing overall project timelines.

Strength and Durability

One of the primary benefits of hollow sections is their exceptional strength and durability. Made from high-quality steel, these sections can withstand significant stress and load, making them suitable for demanding construction projects. The hollow structure enhances their ability to distribute weight evenly, reducing the risk of structural failure.

Lightweight

Despite their strength, hollow sections are relatively lightweight. This characteristic simplifies transportation and handling, reducing labor costs and improving construction efficiency. The lightweight nature of these sections also contributes to faster assembly and disassembly of scaffolding systems, enhancing overall project timelines.

Cost-Effective

Using hollow sections can lead to significant cost savings in construction projects. Their efficient design requires less material to achieve the same structural integrity as solid sections, reducing material costs. Additionally, the ease of fabrication and installation further lowers labor costs, making them a cost-effective solution for builders and engineers.

Aesthetic Appeal

Square hollow sections are particularly noted for their aesthetic appeal. Their clean lines and uniform appearance make them an attractive choice for architectural designs. They are often used in visible structures where visual impact is important, such as building facades and decorative frameworks.