Concrete feels tough, yet it cracks when stretched or pulled. Builders strengthen it with reinforcements that extend its life and performance. Among the strongest reinforcements stands BRC wire mesh, a simple yet powerful grid that transforms fragile slabs into durable structures.

Contractors constantly choose effective solutions that reduce costs, save time, and maintain safety. Across Malaysia, projects rely on sewa scaffolding and sewa staging Malaysia to create stable working platforms, while BRC wire mesh fortifies the concrete. Together, these choices provide unwavering stability, helping construction progress with confidence, efficiency, and strength from the foundation upward.

What is BRC Wire Mesh?

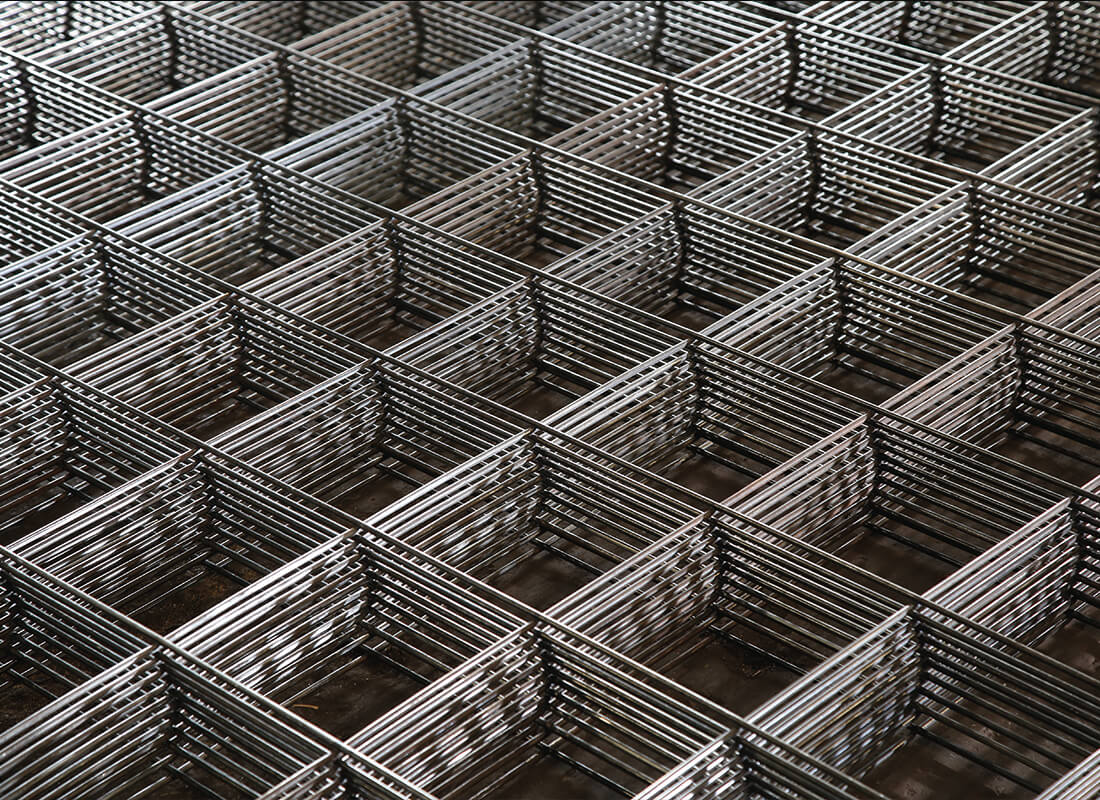

BRC wire mesh forms a welded steel grid where each wire fuses tightly at the crossing point, creating a firm net-like sheet. Once embedded inside concrete, the mesh disperses loads evenly, preventing stress from gathering in one fragile area.

This reinforcement grips the concrete tightly, resisting cracks and extending durability. Builders choose it because it arrives in ready-made sheets that simplify placement and accelerate work. Whether supporting a small slab or a large industrial floor, BRC wire mesh sustains strength, ensures reliability, and keeps concrete performing steadily across countless construction demands.

Applications of BRC Wire Mesh in Construction

1. Foundations

Concrete foundations carry the full weight of a building. Wire mesh BRC spreads these heavy loads evenly into the soil, reducing weak points and preventing sudden settlement. Contractors using sewa scaffolding above ground often rely on mesh below ground to secure stability.

Wire mesh fortifies foundations with a consistent grip, eliminating dangerous weak spots. Solid bases provide unwavering support, allowing structures to remain firm through time. This reinforcement transforms foundations into dependable cores, making every building project safer, steadier, and more resilient against pressure.

2. Floors and Slabs

Floors endure pressure from people, vehicles, and machinery. BRC wire mesh spreads these pressures across the slab, keeping cracks from tearing through the surface. Reinforcement keeps floors smooth and lowers long-term repair costs. Quick installation speeds up construction without slowing other trades.

Mesh-reinforced floors carry heavy loads more effectively. By resisting stress, the reinforcement secures slabs against damage and maintains strength year after year. When builders use sewa staging Johor Bahru, projects move faster, workers operate safely, and owners gain lasting surfaces under constant use.

3. Walls

Concrete walls rise tall, needing reinforcement in both height and width. Wire mesh BRC strengthens these walls by gripping the concrete tightly, keeping them upright against bending or external pressure. Contractors supported by Sewa staging appreciate this strength because it ensures safer and more efficient wall construction at various heights.

Walls reinforced with mesh stay straight and unyielding. The mesh anchors firmly, creating barriers that resist stress and secure buildings against outside forces. Strong walls matter in every project, giving interiors protection and exteriors durability while maintaining structural integrity throughout.

4. Driveways and Pavements

Driveways and pavements bear constant traffic from cars and trucks. Without reinforcement, cracks appear quickly and surfaces deteriorate. Wire mesh BRC shields concrete from stress, binding it firmly to prevent surface damage. Thickness can be adjusted depending on project size and usage.

Reinforced pavements resist long-term wear, lowering future repair costs. Vehicles roll smoothly without breaking the surface, while the reinforcement keeps the pathway solid. Choosing wire mesh ensures outdoor structures withstand years of heavy pressure, making driveways and pavements reliable for residential and commercial sites.

Benefits of Using BRC Wire Mesh

1. Greater Strength

Concrete fails under pulling forces, but BRC wire mesh blocks cracks and disperses tension evenly. Reinforcement increases strength, securing slabs, beams, and walls against stress.

The grid transfers stress smoothly across the structure. With greater strength, projects stand safer, work longer, and support heavier loads without failure. Contractors value this reinforcement because it delivers dependable stability, making BRC in construction reliable across countless applications where strength defines safety.

2. Crack Control

Concrete shrinks and expands with temperature changes, often splitting along the surface. Wire mesh restrains these movements, holding the slab together and reducing surface cracks.

This restraint prevents cracks from spreading widely and weakening the structure. With surfaces intact, BRC in construction remains attractive and sound. Crack control reduces repair needs, helping projects stay efficient while giving builders confidence that structures will resist damage long after completion.

3. Durability

Mesh reinforcement enables concrete to withstand constant pressure, weather changes, and daily wear. Durability rises, reducing the need for costly repairs or frequent maintenance.

Strong grids inside concrete extend its lifespan, ensuring projects endure years of use. Reinforced structures resist stress and continue to perform effectively. Combined with dependable practices like sewa scaffolding, durability expands inside and across the project site, ensuring safety and reliability through every phase.

4. Cost Savings

BRC wire mesh arrives in uniform sheets, simplifying installation and reducing labour. Faster placement lowers project expenses while maintaining consistent quality. Builders often combine mesh with sewa scaffolding for greater savings.

5. Easy Installation

The mesh feels light, carries easily, and sets quickly inside formwork. Workers place it without heavy tools, keeping projects efficient and safe. Simple handling reduces errors and avoids delays. Quick installation allows multiple tasks to advance together, streamlining BRC in construction.

Types & Sizes of BRC Wire Mesh

Light-Duty Mesh

Light-duty mesh suits small slabs and floors that require modest strength. It offers affordable reinforcement for basic BRC in construction needs where heavy stress remains minimal.

Medium-Duty Mesh

Medium-duty mesh supports residential projects needing a balance between cost and strength. It holds daily loads efficiently and works well for houses or small buildings.

Heavy-Duty Mesh

Heavy-duty mesh strengthens commercial floors, beams, and columns. It tolerates heavy machinery and consistent stress, keeping critical structures solid and secure.

Custom Sizes

Manufacturers supply BRC mesh in different gauges and sheet sizes. Builders choose thickness and dimensions suited to the project. Custom sizes ensure a perfect fit and performance.

How BRC Wire Mesh is Installed in Construction

Workers position the BRC mesh in the formwork before pouring concrete. Small blocks lift it slightly so the mesh rests within the slab’s centre. Concrete then flows over it, locking the reinforcement firmly into place.

Accurate placement ensures proper bonding. Careful measurement avoids weak spots and creates strong reinforcement inside the concrete. By installing correctly, crews finish projects quickly and keep job sites safer while achieving higher-quality results in every slab, wall, and foundation.

BRC Wire Mesh vs Traditional Reinforcement

| Feature | BRC Wire Mesh | Traditional Reinforcement |

| Form | Welded sheets | Loose steel bars |

| Installation Speed | Quick placement | Slow tying and binding |

| Labor Cost | Lower | Higher |

| Crack Control | Strong and consistent | Less uniform |

| Waste | Minimal | More cutting and leftover bars |

| Versatility | Ready for slabs, walls, floors | Needs more adjustment |

Buying Guide: How to Choose the Right BRC Wire Mesh

1. Check Project Size

Small slabs need lighter mesh, while larger projects demand heavy-duty grids. Choosing suitable reinforcement keeps costs low and secures structural stability.

2. Look at Load Requirements

Consider expected loads before choosing. Floors carrying heavy traffic or machinery require thicker mesh, while lighter use demands only standard reinforcement.

3. Consider Budget and Efficiency

Pick reinforcement that balances cost with performance. Pairing mesh with sewa staging and sewa scaffolding creates efficient projects without waste.

4. Choose a Reliable Supplier

A dependable supplier provides accurate sizes, strong sheets, and timely deliveries. Reliable sources prevent delays and guarantee smoother project progress from start to finish.

Conclusion

Wire mesh BRC plays a crucial role in construction by reinforcing concrete, stopping cracks, and extending structural life. It spreads loads evenly and installs quickly, helping projects finish safely and affordably. Combined with sewa scaffolding and sewa staging Johor Bahru, it ensures strong, efficient, and dependable results. Every project stands out and steadier when reinforced properly with BRC mesh.

FAQs

Builders use BRC mesh to reinforce concrete, control cracks, and increase durability. It spreads pressure evenly, making structures stronger, safer, and more reliable.

Yes, wire mesh is a great substitute for steel bars in many slabs, floors, and pavements. Larger projects may still demand additional reinforcement depending on design needs.

Yes. It reduces labour, speeds up installation, and prevents future damage. Many combine mesh with sewa scaffolding and sewa staging for efficient, affordable construction.